Declaration Channel

Remarkable Youth: Venture Capital Record | Ecofa: Digital Transformation of the Mold Processing Supply Chain, Exploring Ultimate Efficiency

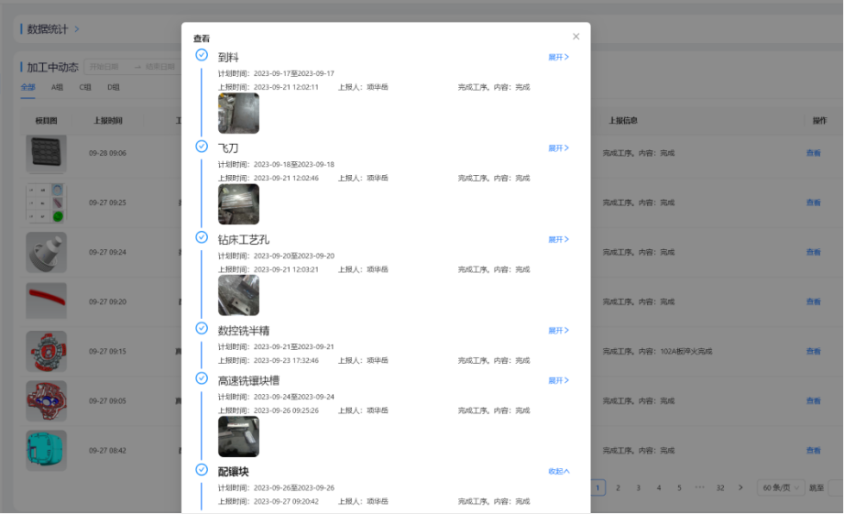

During the Mid-Autumn Festival and National Day holiday, many production equipment in the Taizhou Huangyan mold processing cluster are still running continuously to fulfill orders. One factory that produces automotive molds has entered a refined processing stage after receiving materials, with the entire process planned to last one and a half months, completed through collaboration among multiple processing factories, each handling a single process. The entire production process is recorded and controlled by a platform, as if a meticulous recorder is documenting the mold's machine time, machine operation status, and process flow status, monitoring the state and data of each link. This platform is the "Mold Cloud" platform developed by Nanjing Aikefa IoT Technology Co., Ltd. (referred to as "Aikefa"), which focuses on the digitalization of the mold processing supply chain.

Aikefa is a technology company in the mold manufacturing industry, relying on the strong processing resources and capabilities of domestic mold manufacturing clusters. Through the deconstruction of the mold processing link and the digital transformation of the mold processing supply chain, it achieves optimal production scheduling for mold processing and explores extreme efficiency in the mold supply chain. In 2018, Aikefa was awarded the "Key Industrial Internet Platform of Jiangsu Province"; in 2020, it received the titles of "National High-tech Enterprise" and "Provincial Specialized and Innovative Small Giant"; and in 2021, it was recognized as a "Jiangsu Province Intelligent Manufacturing Demonstration Platform."

Explore the development needs of the mold industry and demonstrate the empowerment plan of the industrial cloud platform.

The industrial internet is an important cornerstone of the Fourth Industrial Revolution and a key lever for achieving the transformation of old and new driving forces. It is based on networks, centered on platforms, driven by data, and secured by safety. It represents an application model deeply integrating the internet, big data, artificial intelligence, and the real economy, leading to the reshaping of supply chains and industrial chains, and improving the quality, efficiency, and cost reduction of the real economy. Therefore, the state attaches great importance to it and proposed to "deeply implement the industrial internet innovation development strategy" in 2017.

Aikefa's CEO, Zhang Kan, studied communication engineering. Due to family involvement in the mold production industry, when the trend of industrial internet emerged, he began to consider whether this traditional industry could be empowered through digitalization and informatization. With this idea, in 2017, Zhang Kan led his team to participate in the selection of outstanding projects for young college students in Nanjing, winning the special prize with the name "Mold Cloud," which received angel investment from the Nanjing Innovation Investment Group and financial support from the Nanjing Human Resources and Social Security Bureau. "For the team, the honor and investment support are both motivation and drive. After that, we focused on the mold track, hoping to truly assist the development of this traditional industry through digitalization and informatization," Zhang Kan introduced when discussing the entrepreneurial opportunity.

"One-third of the world's molds are in China, and one-tenth of the molds in China are in Taizhou Huangyan." Over 70 years of modern mold inheritance has created a deep industrial foundation in Huangyan. Huangyan is known as the "Hometown of Molds in China," currently gathering more than 2,000 mold production and processing enterprises and 150,000 mold processing practitioners, driving the development of a trillion-level industrial chain locally. Therefore, after starting his business, Zhang Kan set the goal of expanding the mold supply chain in Taizhou Huangyan.

After more than a year of research, Zhang Kan and his team found that the mold market is a typical ant market, characterized by industry fragmentation, few giants, price opacity, and obvious short-line processes, meaning that each mold is a different product, 100% non-standard. However, many processing enterprises in the cluster adopt a refined division of labor and collaboration model, with each processing factory only performing a single process, while complex process flows need to connect to different processing factories for collaborative manufacturing. The non-standardized and non-process characteristics also make it difficult for some small and medium-sized product companies to find suitable suppliers in terms of geographical location, capacity, and price.

"Short-line processes lead to many factories in the cluster being small to medium-sized, with limited resources and order-taking capabilities, making it difficult to spend funds on digital upgrades that have certain difficulties. However, by using IoT tools to empower factories with digitalization and informatization, implementing reasonable capacity allocation, and utilizing the Aikefa Mold Cloud platform for collaborative work, efficient delivery is feasible." After three years of in-depth exploration of the current situation and needs of the mold industry, Zhang Kan decided to connect the mold processing cluster through the industrial cloud platform.

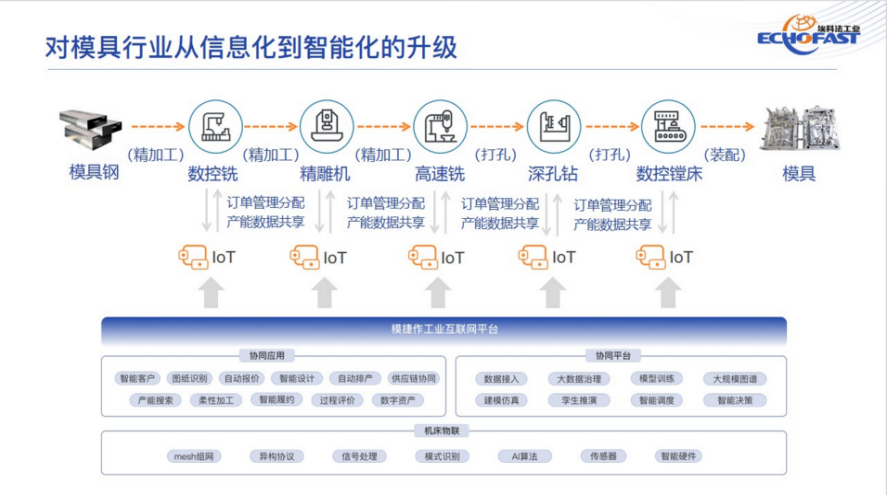

With this idea, Aikefa launched the Mold Cloud industrial internet platform, focusing on "collaborative applications," "collaborative platforms," and "machine tool IoT" as the main modules, connecting 3,631 mold processing machine tools, 493 mold processing households, and 130 mold manufacturing enterprises to finely match mold production needs. Through core functions such as intelligent applications in the mold industry, ecological upstream and downstream collaboration, processing process perception, manufacturing scene IoT, and big data in industrial clusters, it plans and follows up on capacity planning within the cluster, dynamic production scheduling, cross-enterprise material procurement collaboration, cross-temporal and spatial capacity progress collaboration, workpiece ID recognition and flow positioning, and real-time supplier capacity status. In the past, the production and processing of a mold required going through 10 main processes, including CNC milling, high-speed milling, wire cutting, and electrical discharge machining, which meant purchasing the necessary equipment for each process to meet production needs. However, by outsourcing processing through the Mold Cloud collaborative platform, mold factories only need to specialize in a single process, achieving the best quality and optimal price in that process to gain a significant advantage.

Select the right track to gain support from industrial investment, innovation investment, and park investment.

Zhang Kan and his team continue to make efforts in the mold track. After receiving angel fund investment from the venture capital group, in 2019, Aikefa gained recognition from the industry and received a second round of investment from SANY Heavy Industry in Hunan. In 2021, the venture capital group continued to support, joining forces with Qilin Technology Innovation and New Basin Investment to complete the pre-A round investment in Aikefa. The investment team of the venture capital group stated: "Mold processing and manufacturing is a traditional industry with certain barriers but high customer stickiness, with a scale of three to four trillion. However, with the acceleration of the 'Made in China 2025' initiative, the refinement of manufacturing, equipment utilization, efficiency, and quality have all become important market competitiveness. Aikefa not only has its own core mold factory but also achieves the digital upgrade of industrial chain enterprises through collaboration, releasing the potential of industrial internet empowerment and promoting high-quality development of the manufacturing industry."

After the intelligent upgrade of industrial chain enterprises, Aikefa now not only owns a core factory area of 6,000 square meters but can also penetrate into the processing equipment of the cluster, understand processing duration and idle status for effective scheduling, allowing Aikefa's mold processing to achieve an overall efficiency improvement of 30%. It has also gained outstanding advantages in rapid mold design and manufacturing, serving enterprises sensitive to delivery times and costs, transforming Aikefa from a mold processing company with only over one million in revenue to a company with revenues reaching 40 to 50 million.

Using Nanjing as the "brain" for the long-term development of the national integrated supply chain.

2023 is the last year for the implementation of the "Nanjing Manufacturing Industry Digital Transformation Implementation Plan (2021-2023)." The government is actively supporting and promoting the construction of industrial internet platforms, coupled with Nanjing's superior software information technology foundation and intelligent hardware foundation. This is also an important consideration for Zhang Kan to choose Nanjing as the location for the "brain" of the mold cluster.

In China, besides Taizhou Huangyan, there are also six other mold processing clusters including Ningbo Yuyao, Kunshan Huqiao, and Zhongshan Xiaolan. When considering the long-term development and growth of the company, Zhang Kan expressed the hope to use Nanjing as the "brain" to allow the mold cloud platform to radiate nationwide and expand the company's mold business. "On one hand, we hope to replicate the existing experience and model in other clusters, and on the other hand, we consider the expansion of business in the same industry. We believe that the advantages of the mold cloud platform in digitalization and data are not only applicable to product-based company clients but also suitable for peer mold factories. We will assist mold factories in implementing comprehensive control over the mold processing process, striving for information transparency in all links until delivery, which will undoubtedly benefit the company's high turnover and high repurchase rates." After all, the commercial market is fiercely competitive and ever-changing. Breaking through the inherent model and integrating with the supply chain will be easier to win the market than standing in opposition. Targeting the track and focusing on the industry, Zhang Kan is full of expectations for the future.

Source: Venture Capital Group

Reviewed by: Xue Yao

Published by: You Yi

Related Annexes